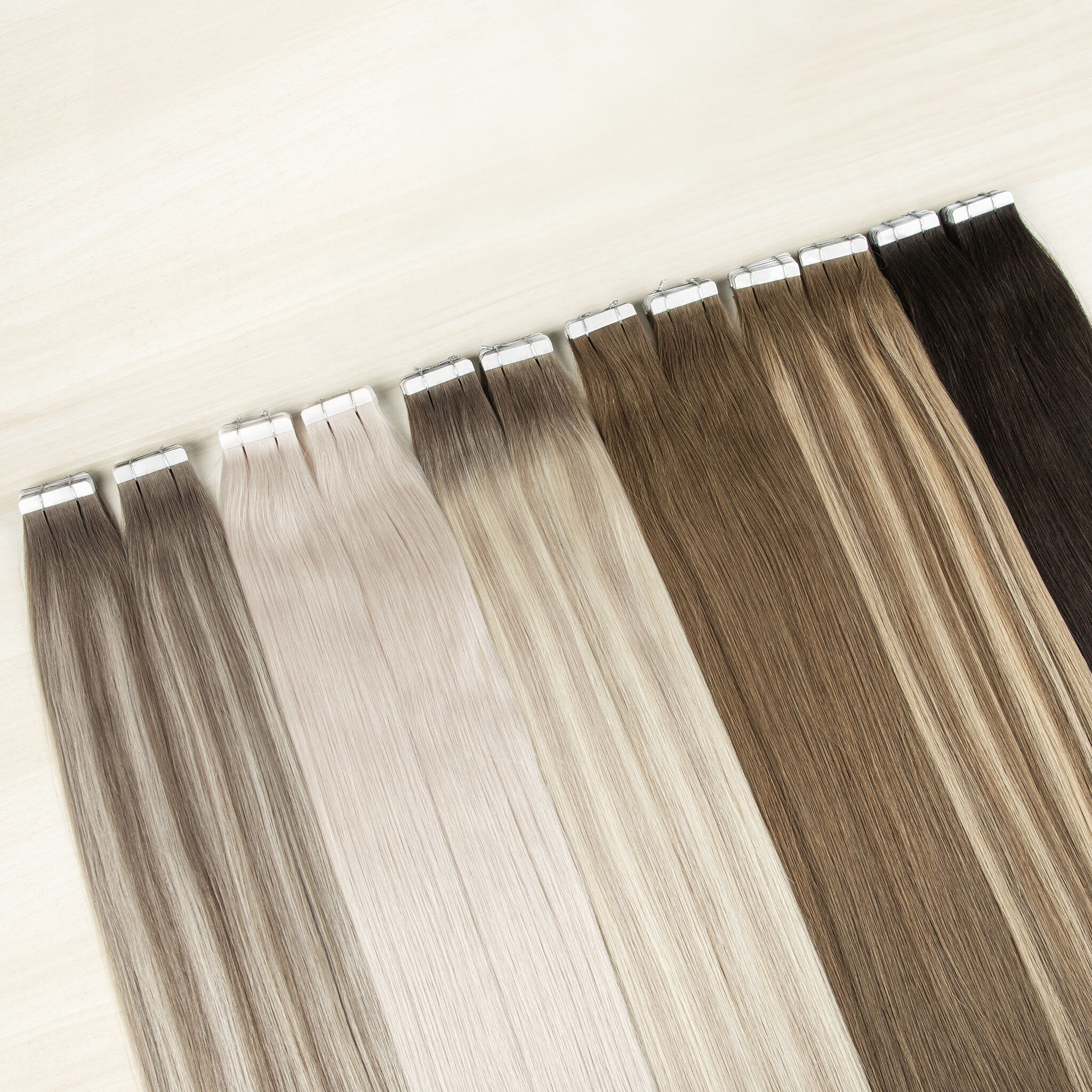

tape in extensions human hair manufacturer

A tape in extensions human hair manufacturer specializes in producing high-quality hair extensions using advanced adhesive technology and premium human hair sources. These manufacturers employ sophisticated processing techniques to create seamless, natural-looking extensions that integrate perfectly with the client's natural hair. The manufacturing process involves careful selection of raw hair materials, typically sourced from ethical suppliers, followed by meticulous cleaning, sorting, and treatment procedures. The hair undergoes multiple quality control checks to ensure consistency in texture, color, and length. The distinctive feature of these manufacturers lies in their specialized adhesive application process, where medical-grade tape is precisely attached to the hair wefts. This technology ensures secure attachment while maintaining the hair's natural movement and appearance. Modern manufacturing facilities utilize state-of-the-art equipment for cutting, coloring, and treating the hair, ensuring each extension meets strict quality standards. The production process also includes innovative packaging solutions that preserve the integrity of the tape adhesive until application. These manufacturers often provide customization options, including various lengths, colors, and textures, catering to diverse client needs and preferences.