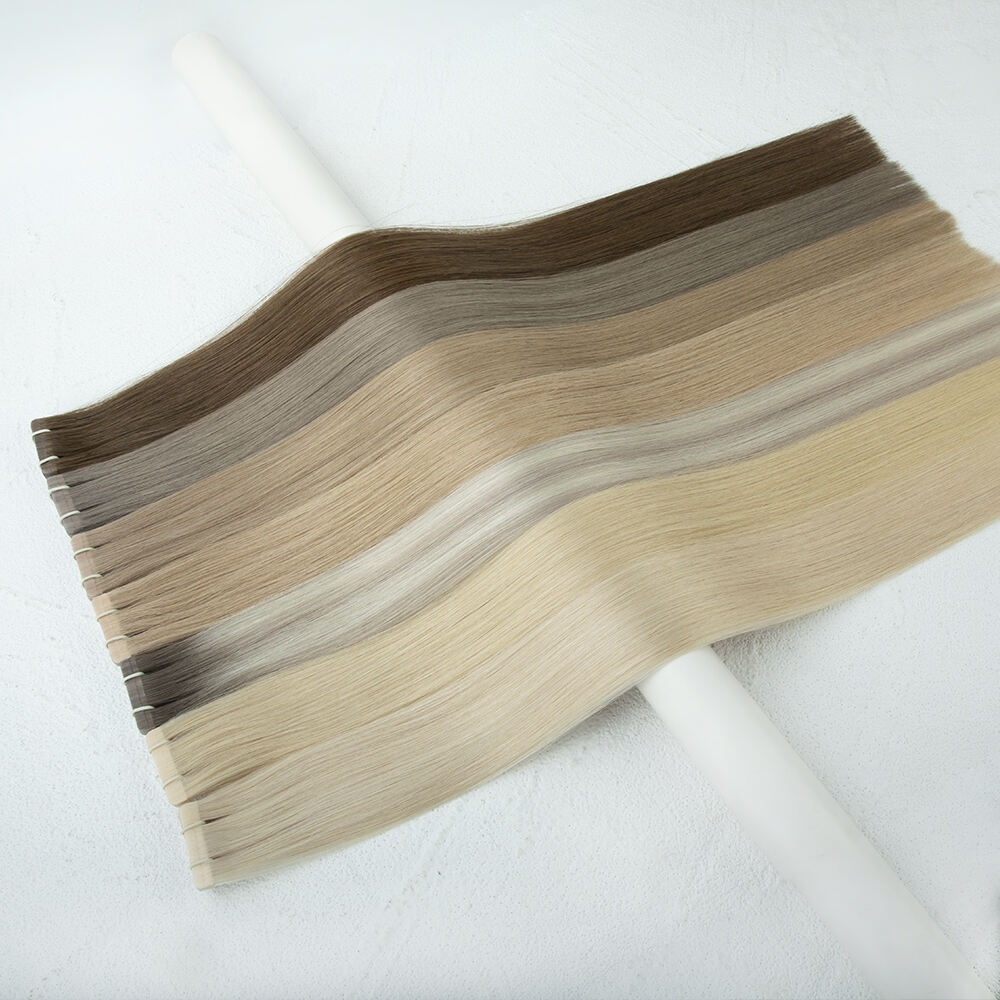

tape hair factory

A tape hair factory represents a cutting-edge manufacturing facility dedicated to producing high-quality tape-in hair extensions. These specialized facilities combine advanced machinery with precise quality control systems to create seamless, professional-grade hair extensions. The production process involves carefully selecting premium human hair, treating it through multiple refinement stages, and applying medical-grade adhesive tape. Modern tape hair factories utilize automated systems for consistent tape application while maintaining strict quality standards throughout the manufacturing process. The facilities are equipped with specialized cleaning and conditioning stations, precise cutting machinery, and advanced color treatment areas. Quality control checkpoints are strategically placed throughout the production line, ensuring each hair weft meets exact specifications for thickness, length, and tape adhesion strength. Environmental controls maintain optimal temperature and humidity levels to preserve hair quality and ensure proper tape adhesion. These factories also incorporate research and development departments focused on improving tape adhesive technology and hair treatment methods. The final products undergo rigorous testing for durability, comfort, and natural appearance before packaging and distribution.